Who Is ArkEdge Space?

Do you know of the company ArkEdge Space? Some readers may have encountered this name for the first time by clicking on this article. Although there are intriguing stories about ArkEdge Space about its founding and early days, let’s save those for later and get started with a brief overview of the company.

ArkEdge Space is a space startup headquartered in Ariake, Koto-ku, Tokyo, Japan. Founded in 2018, it is still a relatively new company, but it has been expanding rapidly—its team has grown to about 150 (as of January 2025) and continues to increase at a pace of about 50 people annually.

Beyond is the famous Tokyo Big Sight, which many of you may recognize. When you cross this bridge in the opposite direction…

You will see Ariake Coliseum and Ariake Tennis Forest Park. ArkEdge Space’s headquarters is located behind them.

Mr. Tomoaki Yasuda, Executive Officer of the Corporate Planning Department, showed me around the company. Mr. Yasuda chuckled and explained “People often tell us that they do not know what kind of company we are,” but in short, “ArkEdge Space is a general integrator of micro-satellite systems.”

Mr. Tomoaki Yasuda, Executive Officer of the Corporate Planning Department ArkEdge Space

Customers aren’t simply looking to buy satellites—they need services that satellite systems can provide. However, it is very difficult for people outside the space industry to understand how to determine which type of satellite to use and what procedures are needed. That’s where an integrator comes in–being a helpful partner that coordinates all of these matters. The concept is similar to what we see in other industries such as IT and robotics.

The author believes that ArkEdge Space is unique among Japan’s numerous space startups due to its wide range of missions. While typical space startups focus resources on a specific area of expertise, such as Earth observation or lunar exploration, ArkEdge Space is involved in not only Earth observation, but also communications, positioning and even the development of a comet exploration probe.

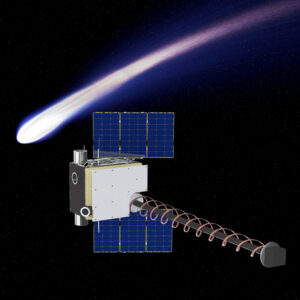

The Japan Aerospace Exploration Agency (JAXA) will provide the “B1” probe for “Comet Interceptor,” the cometary explorer of the European Space Agency (ESA). ArkEdge Space was selected as the development manufacturer for that probe.

As described above, many employees work in the spacious office at the company’s headquarters to carry out a wide range of missions. In addition to designing and developing micro-satellites, the company also provides satellite operation services. Their office floor includes a clean room for development, a radio-frequency anechoic chamber for RF testing, and a satellite mission control center for managing satellite operations.

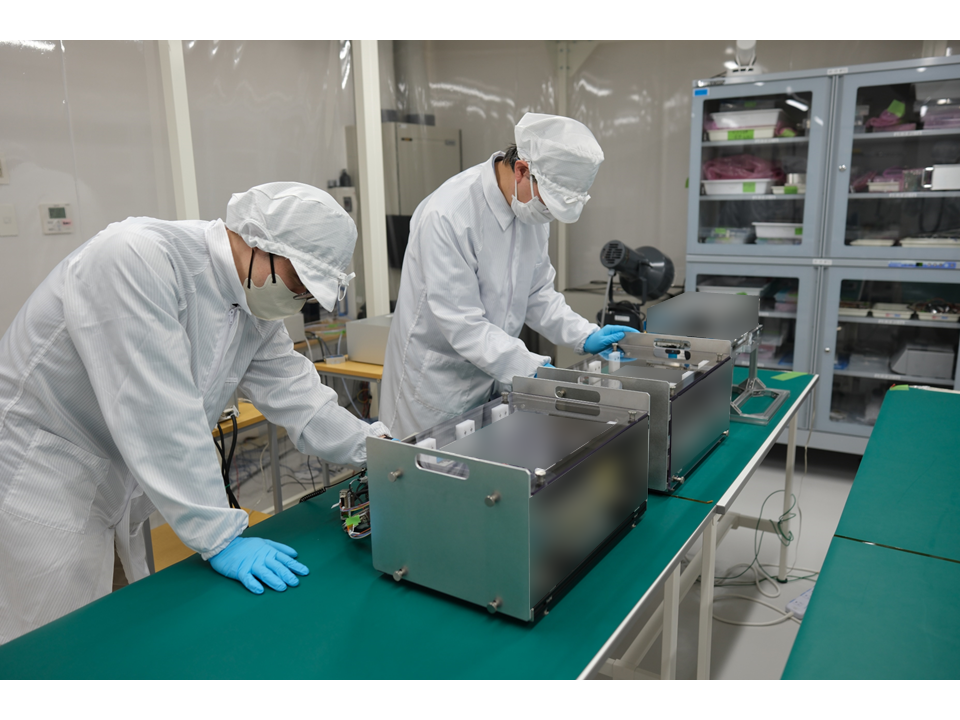

The large screen on the office wall displays the real-time positions of the satellites that the company is operating. In the clean room, dust and other airborne particles are kept below a certain level. This is an essential facility for satellite development.

In the clean room, dust and other airborne particles are kept below a certain level. This is an essential facility for satellite development.

Mission Control Center (MCC): Satellites are operated from the control room such as command transmissions.

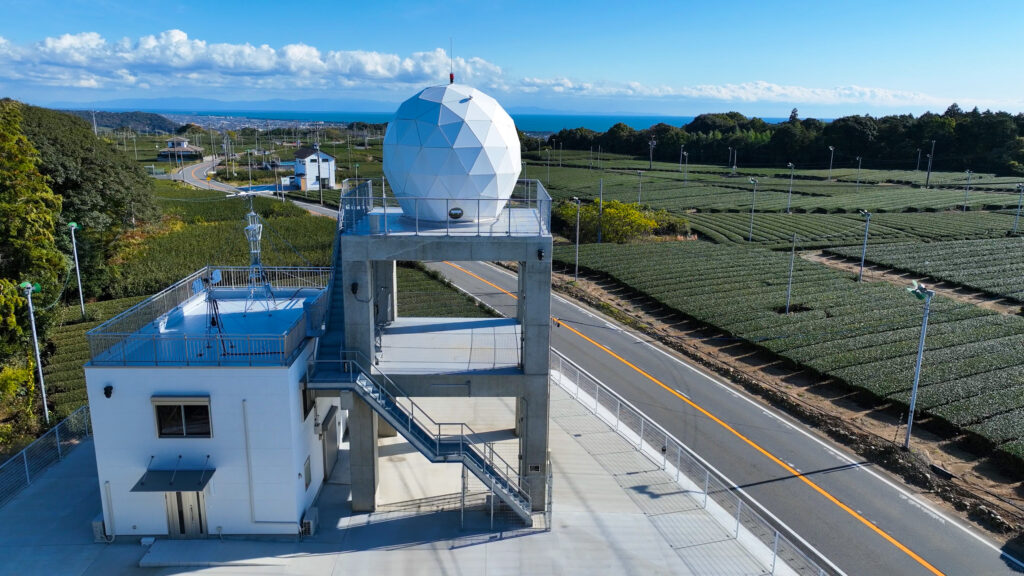

ArkEdge Space also has a ground station in Makinohara City, Shizuoka prefecture, Japan.

ArkEdge Space also has a ground station in Makinohara City, Shizuoka prefecture, Japan.

The Rise of the 6U CubeSat!

This article introduces a 6U size micro-satellite that ArkEdge Space is now developing. As the name suggests, this 6U satellite is a very compact satellite. To give a reader a sense of scale: while conventional large satellites can weigh a few tons at least, a 6U weighs only about 10 kg. Its physical size is equivalent to stacking six 10 cm × 10 cm × 10 cm cubes in a 2×3 configuration—therefore, it’s called a 6U CubeSat.

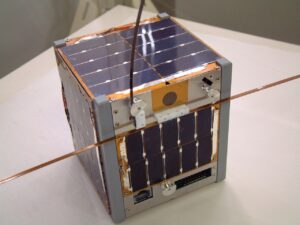

One of the world’s first CubeSats is the “XI-IV” (XI is an acronym for X-factor Investigator), which was launched in 2003. The XI-IV was developed in Professor Shinichi Nakasuka’s laboratory at the University of Tokyo. ArkEdge Space technologies originated in this laboratory.

The XI-IV developed at the University of Tokyo. Despite its 1U size, it took several hundred photos of the Earth and transmitted them to the ground.

Initially, CubeSats were mainly designed for educational and research purpose. However, as the size and weight of high-performance electronic equipment has been reduced as electronics evolve, CubeSat performance has become quite practical. Although what can be done with the 1U is limited as is to be expected, the 6U class provides quite a large space for observational equipment, hitting a sweet spot in terms of “a good size”.

So many models of CubeSats have been used in Japan and internationally, that it is impossible to introduce them all here. For example, the “SPHERE-1 EYE” jointly developed by Sony, the University of Tokyo, and JAXA made a headline because it enabled general public to take photos of the Earth and space. In addition, “OMOTENASHI” (JAXA) and “EQUULEUS” (the University of Tokyo and JAXA) went to the Moon, while “MarCO” (NASA) went to Mars, demonstrating the potential to be used in deep space.

Ultra-small lunar probe, “EQUULEUS”

Key advantages of micro-satellites are that they can be developed rapidly at low cost and in much shorter timeframe. Development costs range from tens to hundreds of millions of Japanese yen, which is one-hundredth or less of the costs of a conventional large satellite. The development period from start to launch is about one to three years.

For reference, even though micro-satellite performance has improved, they cannot completely replace large satellites. For example, the aperture of a telescope greatly affects its resolution during Earth observation a constraint dictated by physics. Micro-satellites, which have severe size constraints, cannot surpass large satellites in terms of resolution.

However, because micro-satellites can be developed rapidly at lower cost, they can be launched in large numbers. While a single large satellite might only be able to take images of a specific location every few days, a constellation of small satellites can capture even several images within a single day. These two—micro-satellites and large satellites—can complement each other by leveraging their respective strengths.

The Built-in Software is Opened to the Public

For this article, Nobuhiro Funabiki, General Manager of Production Department, introduced the 6U satellites from ArkEdge Space. During his time at the University of Tokyo, he was involved in the aforementioned development of EQUULEUS. At ArkEdge Space, he led the effort to build a mass-production framework for 6U satellites.

Nobuhiro Funabiki, General Manager of Production Department at ArkEdge Space, holding a mockup of a 6U satellite

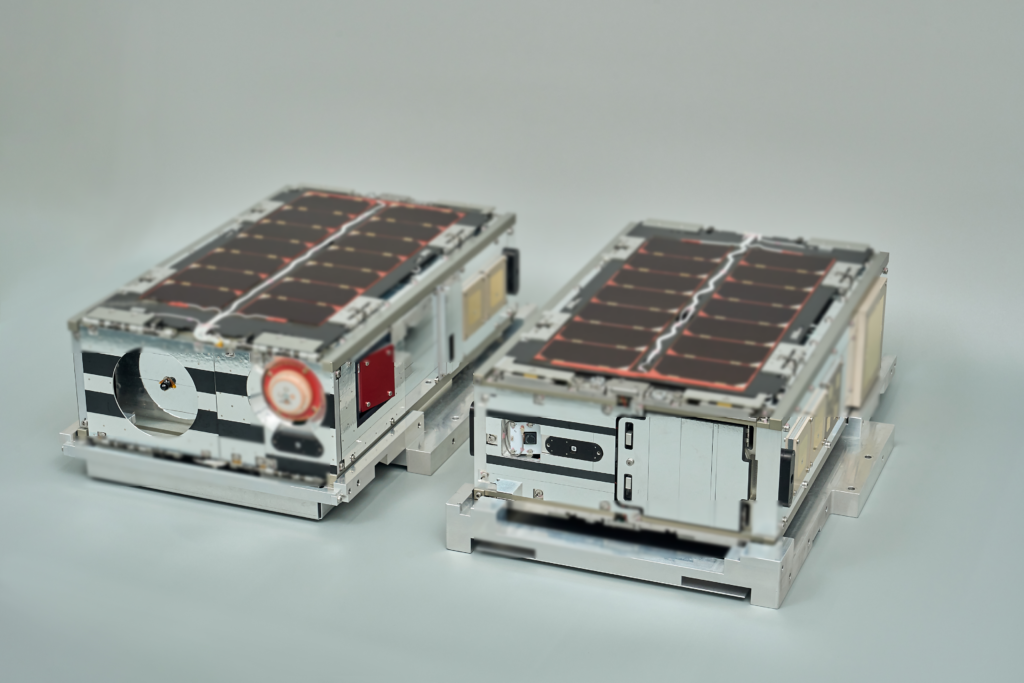

In November 2024, ArkEdge Space completed the development of a multi-purpose bus for 6U satellites, the AE6U, and announced that they would launch seven satellites utilizing it by the end of FY2025.

A satellite bus is a general term for the basic functions required of every satellite, such as communication, an attitude control system, batteries, and on-board computers (OBCs). This is indeed the foundation of a satellite. In contrast to this bus section, the mission section is the portion that differs depending on the purpose of the satellite. For example, the mission section of an Earth observation satellite contains a telescope.

Fully customizing satellites from scratch each time would be costly and time-consuming. By standardizing the bus, you can develop satellites more rapidly and inexpensively because you only have to focus on developing the mission payload. This approach has become the norm of recent commercial satellites.

The University of Tokyo has developed the ISSL6U bus through the development of the aforementioned SPHERE-1 EYE and ONGLAISAT with the Taiwan Space Agency. The AE6U bus from ArkEdge Space is based on this ISSL6U bus, but with enhancements aimed at easier assembly and commercialization.

According to Mr. Funabiki, ArkEdge Space has adopted many software engineering principles practiced in the software industry into their satellite design and development processes. For example, they have open-sourced software and made public the built-in software and development tools for satellites. He said that this helps streamline integration with users, thereby reducing development costs.

Furthermore, the company converts satellite design data into text data that is version-controlled. By inputting this data into a tool that automatically analyzes mission successes, they can check whether operation in a given orbit is free of thermal or electricity issues more quickly and easily. This automation of design validation is another contributor to reduce costs by reducing labor.

Building a System to Mass-produce Several Tens of Satellites per Year

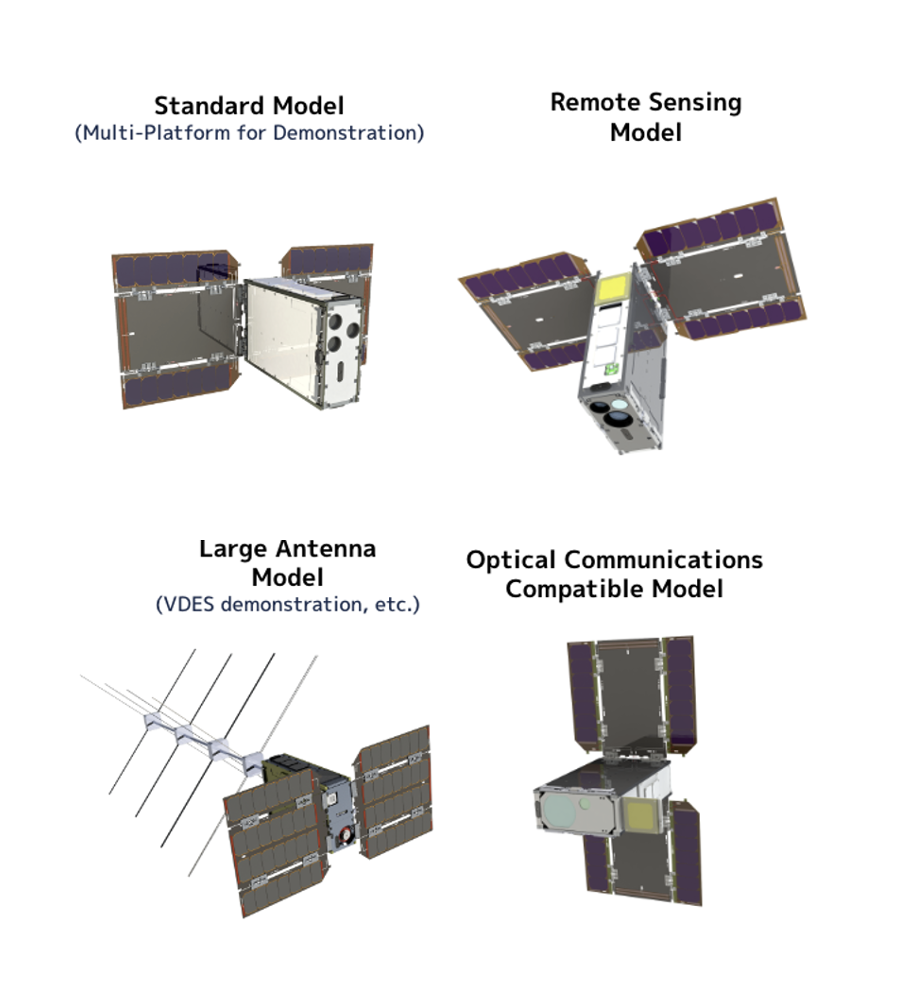

The 6U satellite consists of two sets of 3U. The AE6U bus allows the entire set of 3U to be used as the mission payload. Even a long telescope for Earth observation can be accommodated by using the 3U on the long side as the mission part. Other mission types in development include satellites with a deployable large built-in antenna or those requiring more precise attitude control for optical communications.

The company has already completed three AE6U-based satellites. The first was the AE1b (YODAKA), the mission of which was conceptualized by students at Hanamaki Kita High School. It was released from the International Space Station (ISS) on December 9, 2024. The other two were launched on January 15, 2025. One has the aforementioned deployable built-in antenna, while the other is designed to demonstrate components for space use.

The company has already completed three AE6U-based satellites. The first was the AE1b (YODAKA), the mission of which was conceptualized by students at Hanamaki Kita High School. It was released from the International Space Station (ISS) on December 9, 2024. The other two were launched on January 15, 2025. One has the aforementioned deployable built-in antenna, while the other is designed to demonstrate components for space use.

AE1b (YODAKA) released from the ISS. The satellite’s development was commissioned by Space BD Inc.

AE1c and AE1d were launched after AE1b. Their in-orbit checkout also completed successfully and started their demonstrations.

With successful demonstrations in orbit, the company sees the full-scale mass production will be within their reach. As a strength of micro-satellites is that it is possible to build a satellite “constellation”, where multiple satellites work as a system, it is essential to build a mass-production framework that can handle several tens of satellites.

In fact, ArkEdge Space is already steadily building this mass production infrastructure. The company designs and develops mass-produced satellites in-house. For a part of manufacturing, it works closely with trusted partner companies, outsourcing assembly and testing. As factory data is shared with the Ariake headquarters in real-time, issues can be addressed promptly.

If they tried to handle all mass-production processes themselves, they would need a large capital investment to build factories and would incur fixed costs even when demand is low. By leveraging external facilities, the company can scale more flexible operations. Partners also benefit by being able to effectively utilize equipment that would otherwise go unused to manufacture satellites.

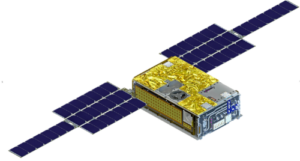

While advancing its 6U satellites into practical use, ArkEdge Space has already started to design larger-class satellites, which is over 50-kg-class. Although the base concept remains similar to that of 6U satellites, over 50-kg-class satellites allow greater freedom in equipment layout, enabling more fully-fledged applications compared to 6U satellites. As 6U’s external form is largely restricted as to be stored in the release mechanism.

That said, the development costs will increase. It may be relatively difficult for regular companies to abruptly start with 50-kg-class satellites. A more realistic path is to first demonstrate key technologies in orbit with a 6U satellite, then scale up to 50-kg class satellites with full-fledged service.

By the Way, What Is This Series?

Let me wrap up this article by introducing myself. I am Minoru Otsuka, a freelance writer. I have been covering the space industry for more than 20 years and have interviewed many space startups along the way. Each one has its own strengths and unique characteristics, but I am particularly impressed with ArkEdge Space as it stands out with its impressive speed and momentum in business.

In this series (made available on the ArkEdge Space website) I hope to offer an outsider’s perspective on the company’s technologies and missions easier to understand. This series will continue for a while, so please stay tuned for the next article!